ExactFlat Pattern Making For Rhino 3D Workflow is Easy to Learn

This Video demonstrates ExactFlat’s 3D to 2D digital pattern making work for Rhino 3D. It introduces the workflow and skills needed to become a successful pattern maker using 3D to 2D digital tools. Unlike other pattern making tools which can take weeks or months to learn, ExactFlat is easy to use and easy to learn. This is because: ExactFlat works within popular 3D CAD software, it uses a simplified workflow, and there is an abundance of schools, training centers, resellers, and trained professionals.

First, ExactFlat is easy to use because it works within two of the most popular 3D CAD programs - Solidworks 3D and Rhino 3D (this video relates to Rhino 3D). The interface and conventions of those tools are maintained within ExactFlat. Familiarity with these CAD programs means you can learn ExactFlat 3D to 2D digital patterning fast.

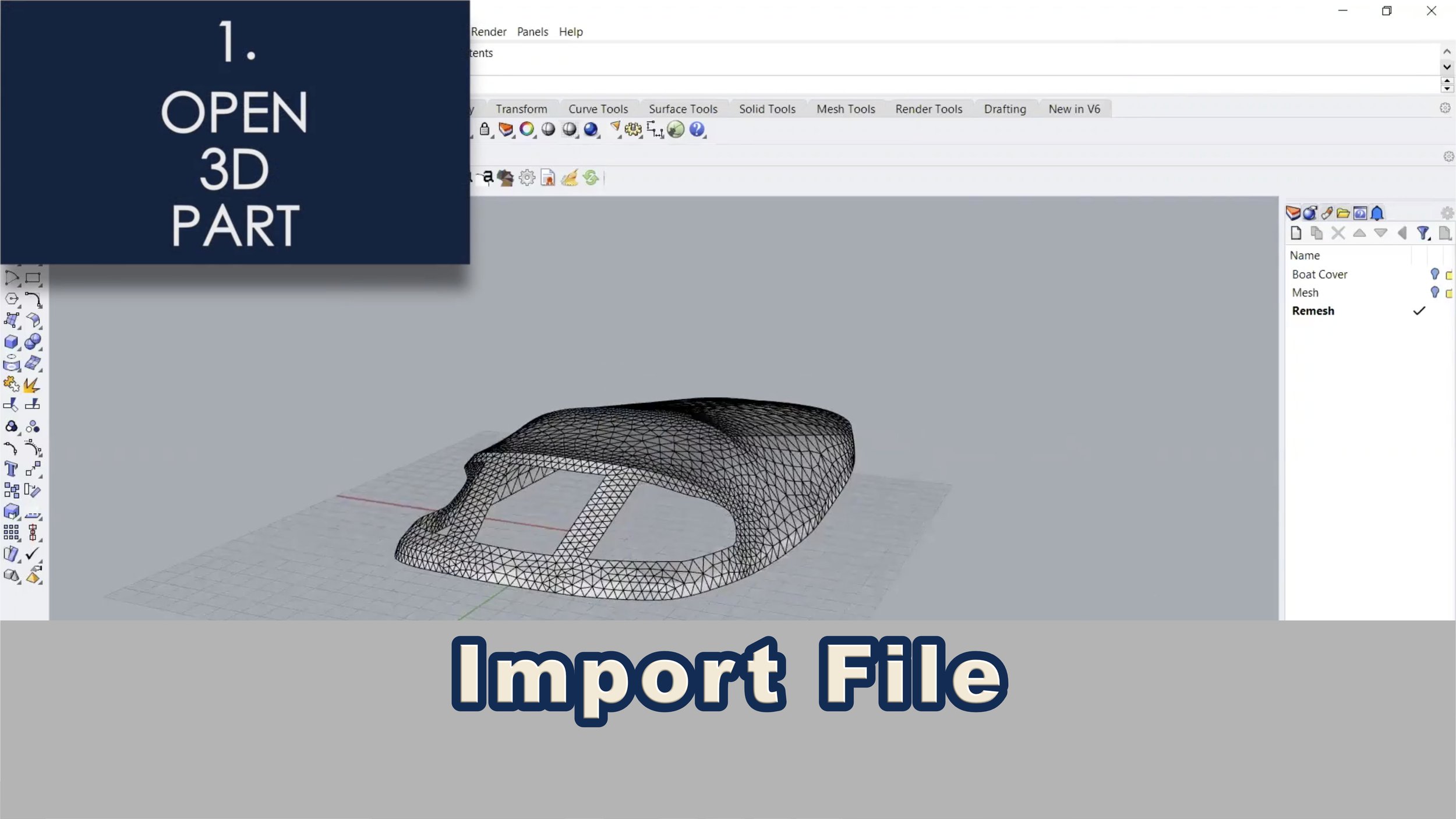

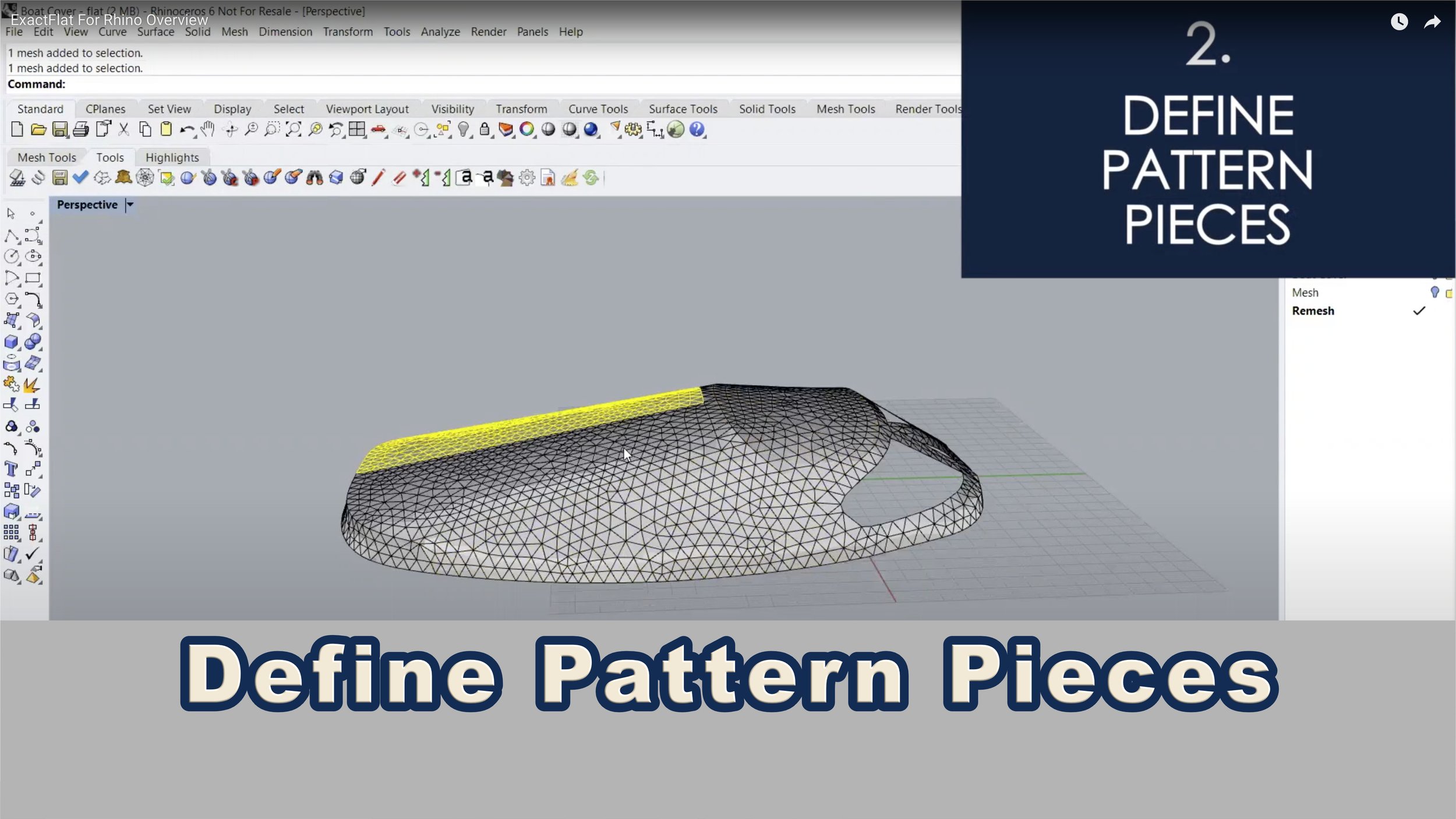

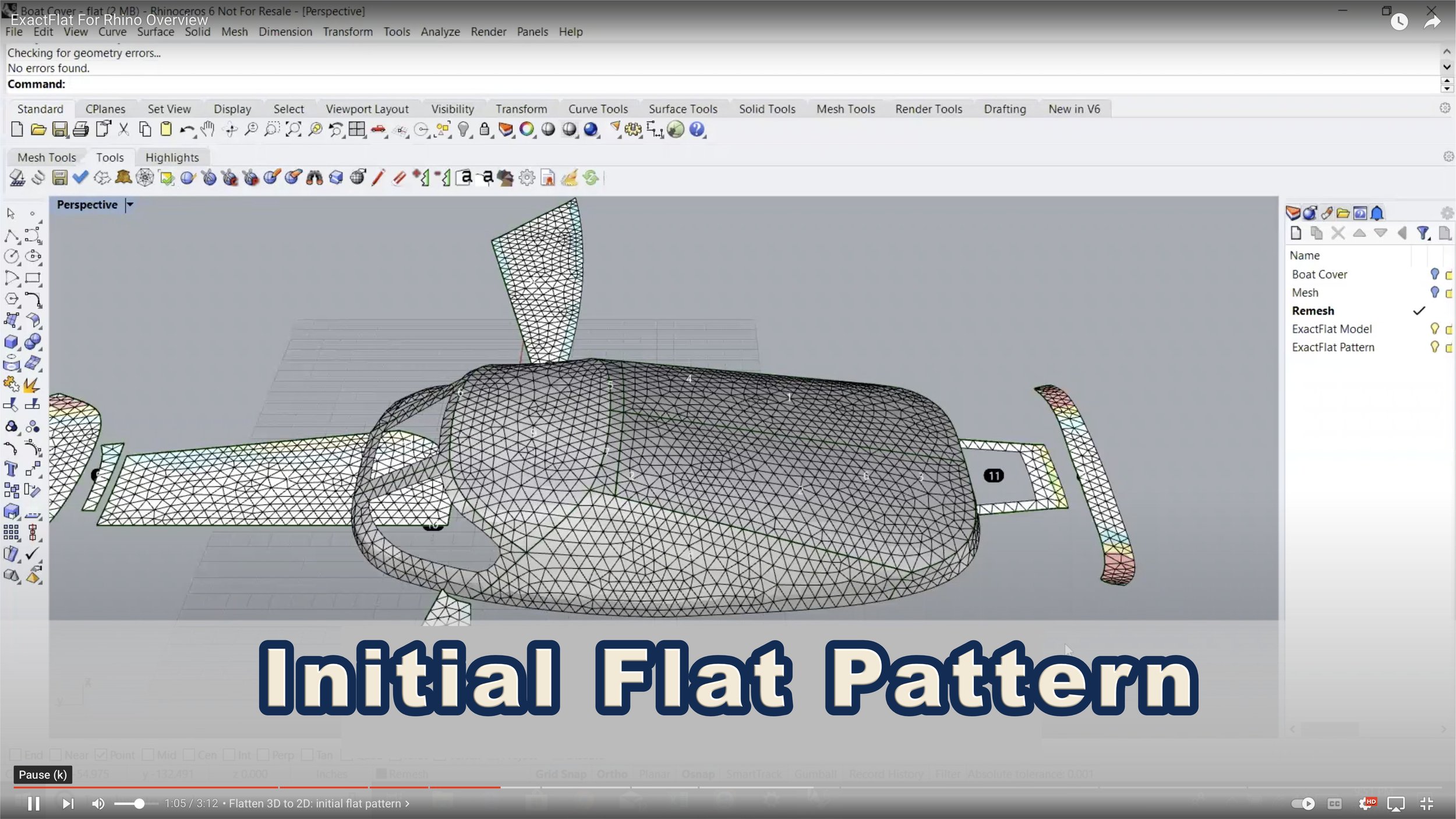

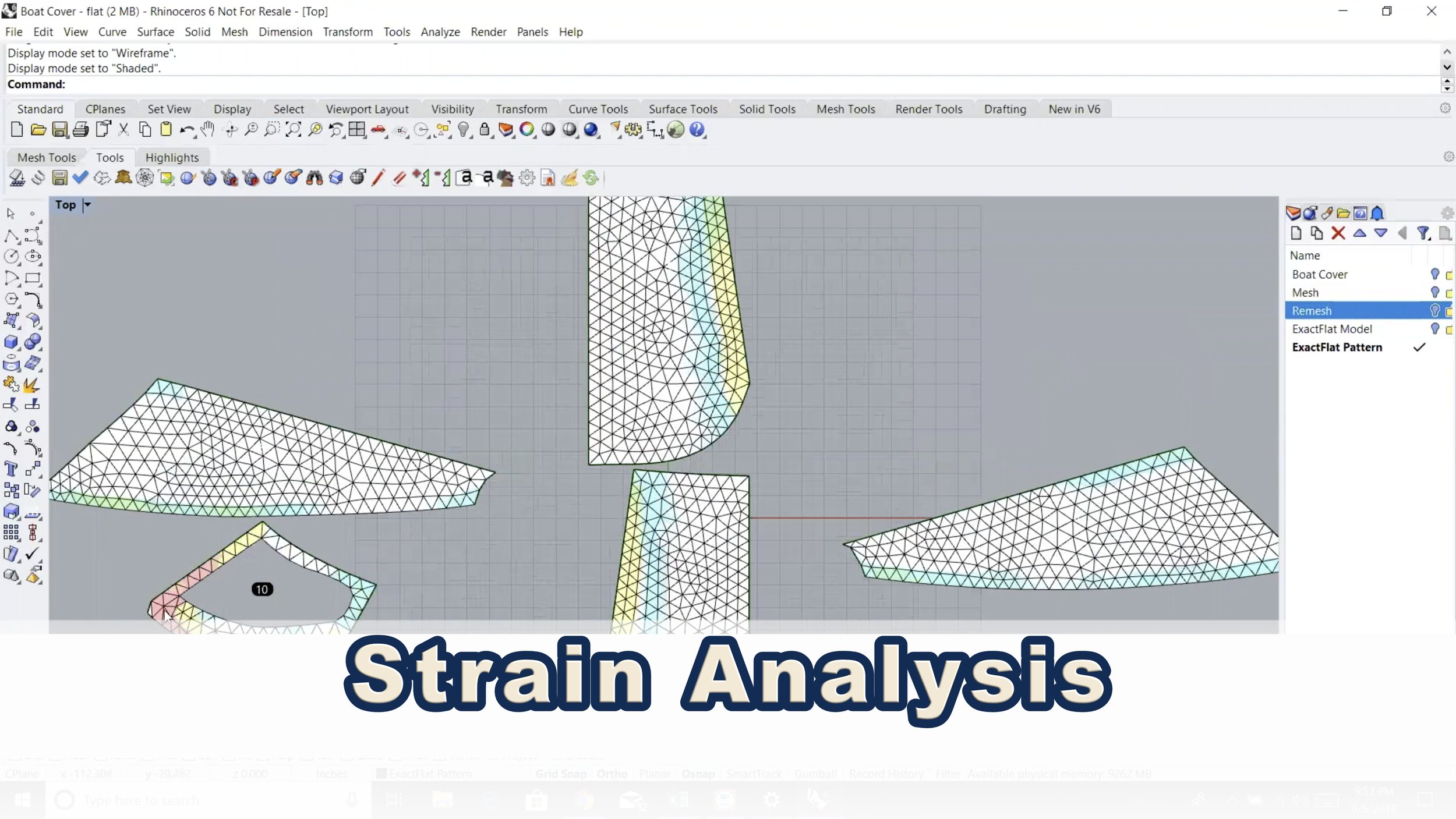

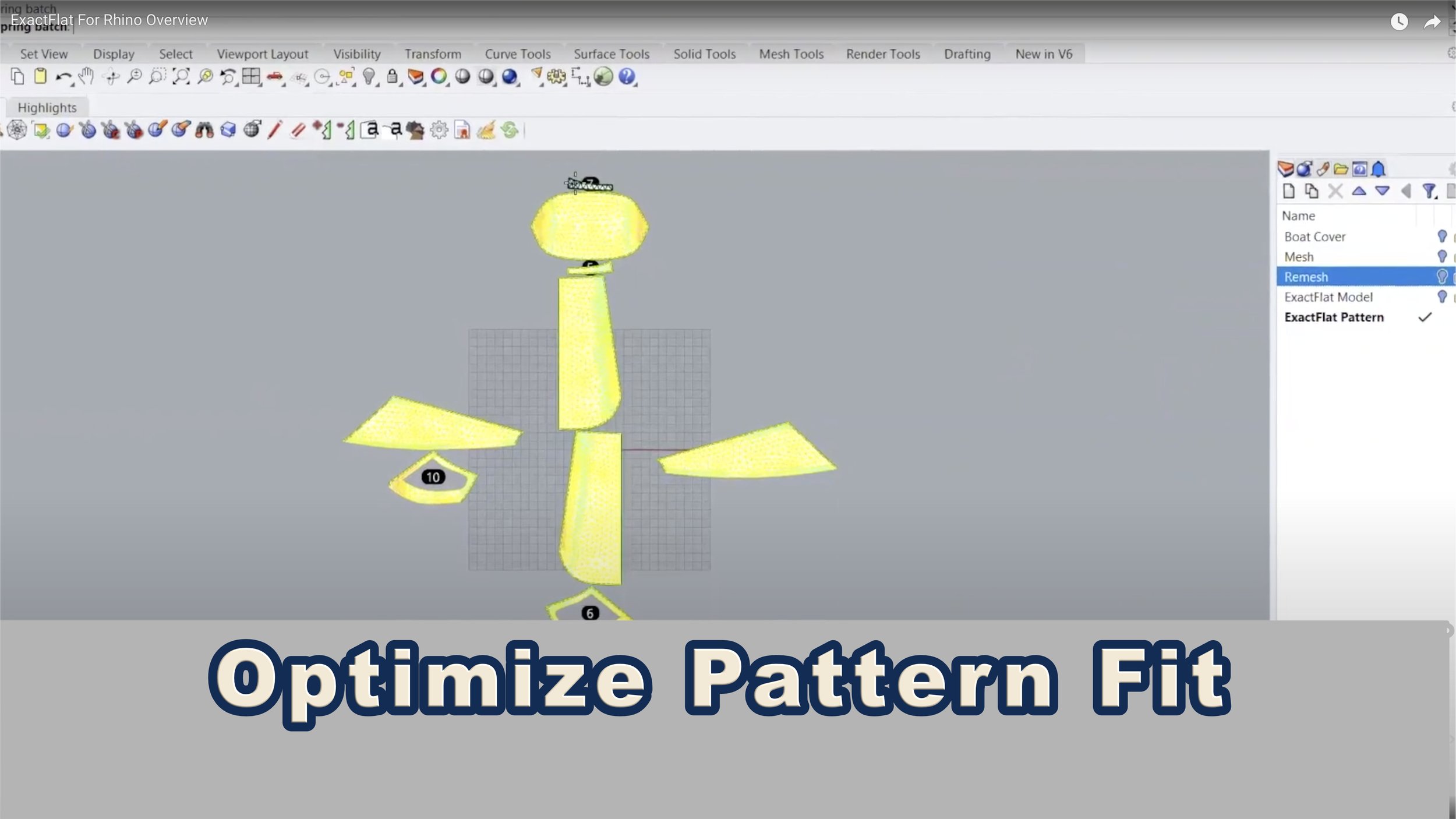

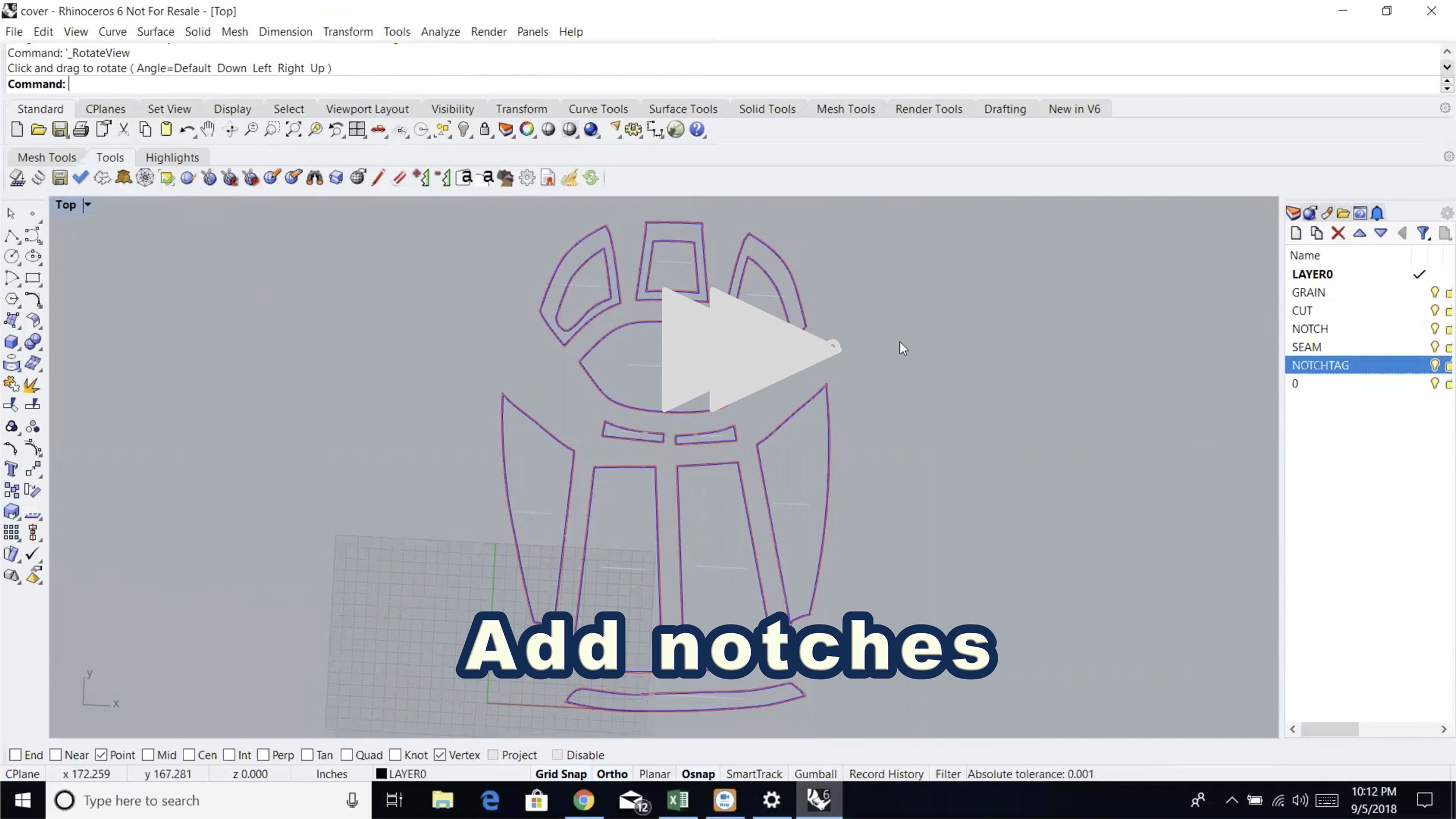

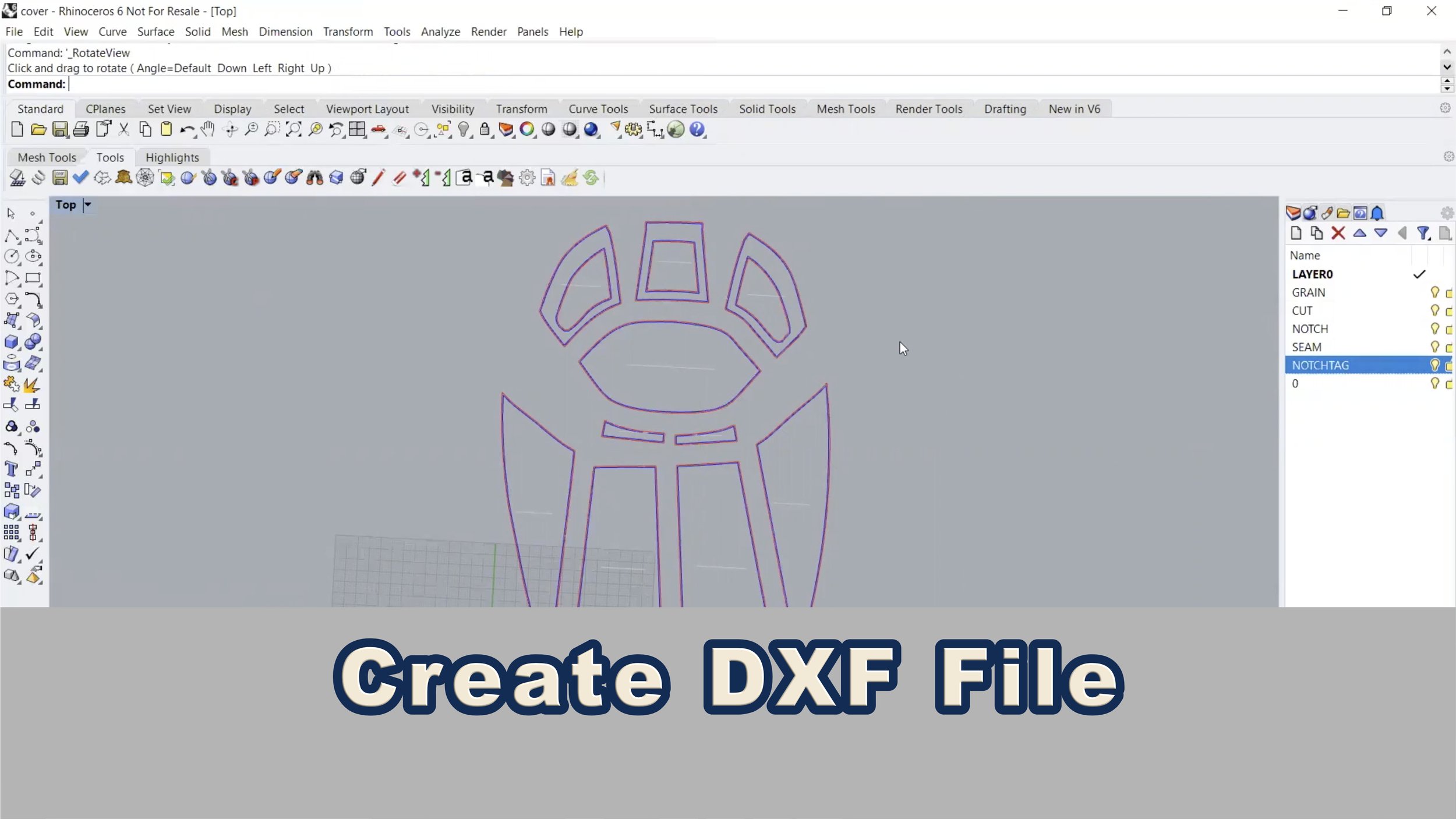

Second, ExactFlalt is easy to use because of its’ simplified workflow to go from 3D to 2D. The most common process involves 5 steps that can be completed in as little as 5 minutes. Most projects can be turned around in 30 minutes or less. This will make your pattern making agile and easy to learn.

Lastly, ExactFlat is easy to learn because there is a massive ecosystem of trained 3D CAD users in addition to a widely distributed network of training options to learn these 3D CAD programs. For users familiar with 3D CAD, it usually takes no more than 4 hours to learn ExactFlat because many of the conventions are similar to those in 3D CAD. Unlike other software, you can get trained and find trained people faster.

To see the full 3D to 2D digital patterning process for yourself watch the video below.

The timecode table of contents is shown below. Clink on the time stamps to be taken directly to that section of the video: