ExactFlat is 3D to 2D digital pattern making software

Busy professionals use ExactFlat for 3D to 2D flattening and to make accurate, error free patterns faster than ever before.

The ExactFlat Workflow is Fast and Easy

Step 1: Prepare 3D Model

Import your 3D Model into ExactFlat using a variety of supported formats.

Adjust pattern splits using delete, split and join commands.

Optimize 3D mesh elements’ size, structure and count using ExactFlat’s Uniform and Adaptive Remesher.

Step 2: Convert 3D to 2D

Disassemble your 3D model into individual 2D pattern pieces.

Relax and de-wrinkle initial strain and sag on 2D pattern pieces.

Optimize fit by refining edge length, surface area, and 2D geometry to intended pattern fit.

Step 3: Finalize 2D Pattern

Arrange 2D pieces quickly to visually mimic the final sewn pattern assembly.

Add seam allowances, alignment notches, markings, and other features.

Create export files in DXF, PDF, or CAD formats for maximum compatibility with follow-on processes.

Marine cockpit cover, 3D digitized and flattened into 2D patterns with ExactFlat.

3D to 2D Piece-linking

for Task Automation

ExactFlat is better because it uses 3D to 2D pattern-linking technology to make pattern making faster, easier, less error-prone, and more accurate:

Automatically Link Adjacent Pattern Pieces in 3D: Automatically link adjacent pattern pieces and edges in 3D for faster, easier pattern design and creation.

Piece-linking

Maintain Links from 3D to 2D: Keep pattern piece links intact from 3D model to 2D pattern, ensuring consistency and accuracy.

Link from 3D to 2D

Trigger Automatic Updates: Changes to one piece automatically trigger updates to adjacent pieces, streamlining adjustments and reducing errors. Pattern piece-linking from 3D to 2D enables fully automated pattern making for even faster time savings

Automation

Automate Seam Allowances & Notches: Linked edges enable edge features like automatically mirroring seams, notches, and end conditions on adjacent edges resulting in faster pattern making. Default settings for edge profiles make it even faster.

Edge Profiles

Find and Arrangement 2D Pieces: Speed up and simplify the visual arrangement of 2D pieces to match the final sewn assembly layout. With piece-linking this complex process is simplified and much faster

Find Pieces

Make Better Patterns Faster. We’ll Show You How.

Advanced Tools For Advanced Projects

ExactFlat is better because it offers a variety of advanced tools and features that make working with complex 3D surfaces, diverse material types, and large projects accurate, fast, and easy. This includes:

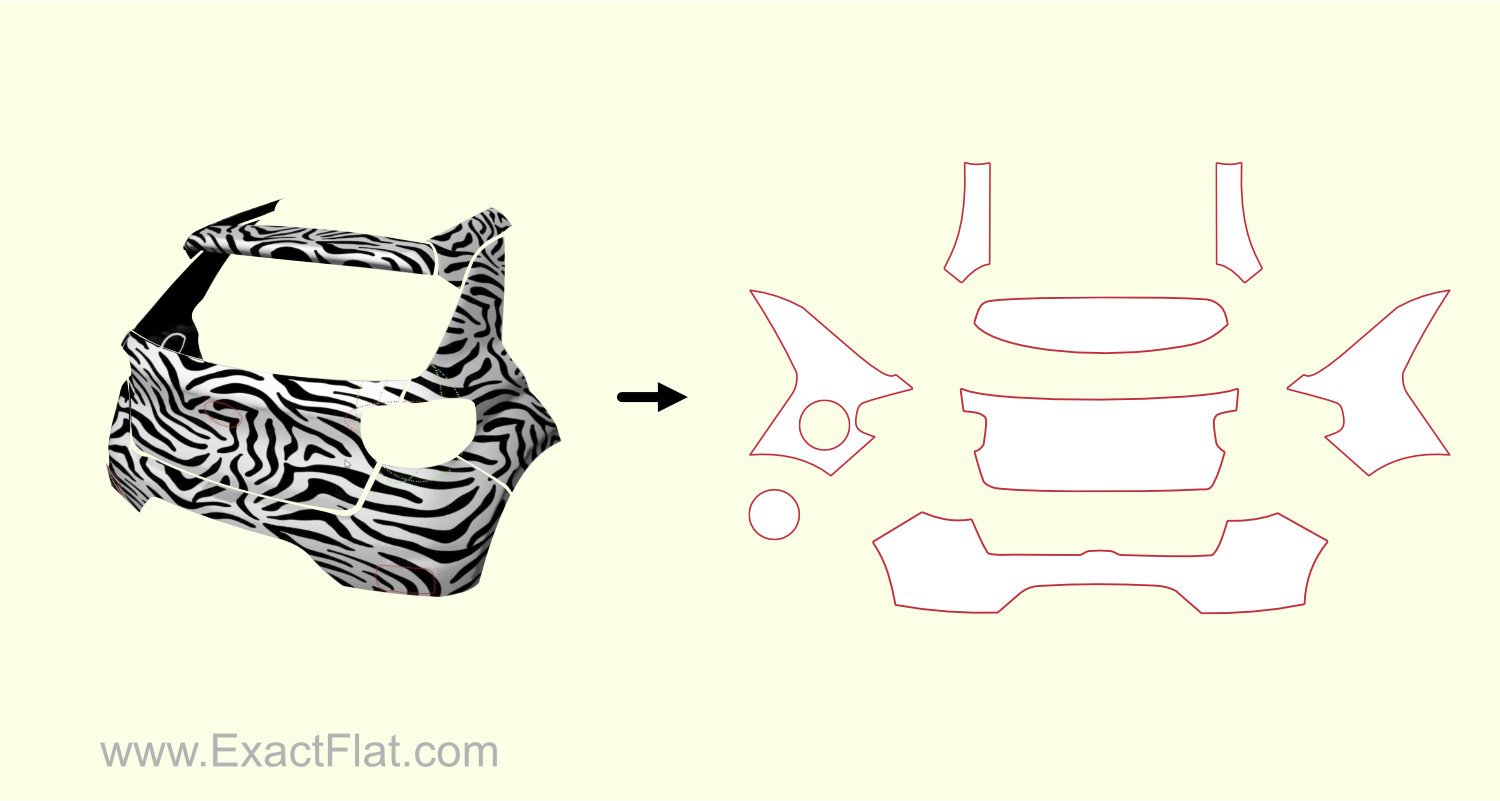

3D scan, zebra print graphic. Flattened with ExactFlat for paint protection film template.

Splits

Create Pattern Piece Splits: Quickly generate pattern pieces by joining, deleting, or splitting faces, allowing for flexible customization.

Darts & Cuts

Add Darts & Relief Cuts: Simplify the inclusion of darts and relief cuts, crucial for shaping and fine-tuning pattern fit.

Piece Names

Name Pieces: Assign standard or custom piece names to easily manage and organize your patterns.

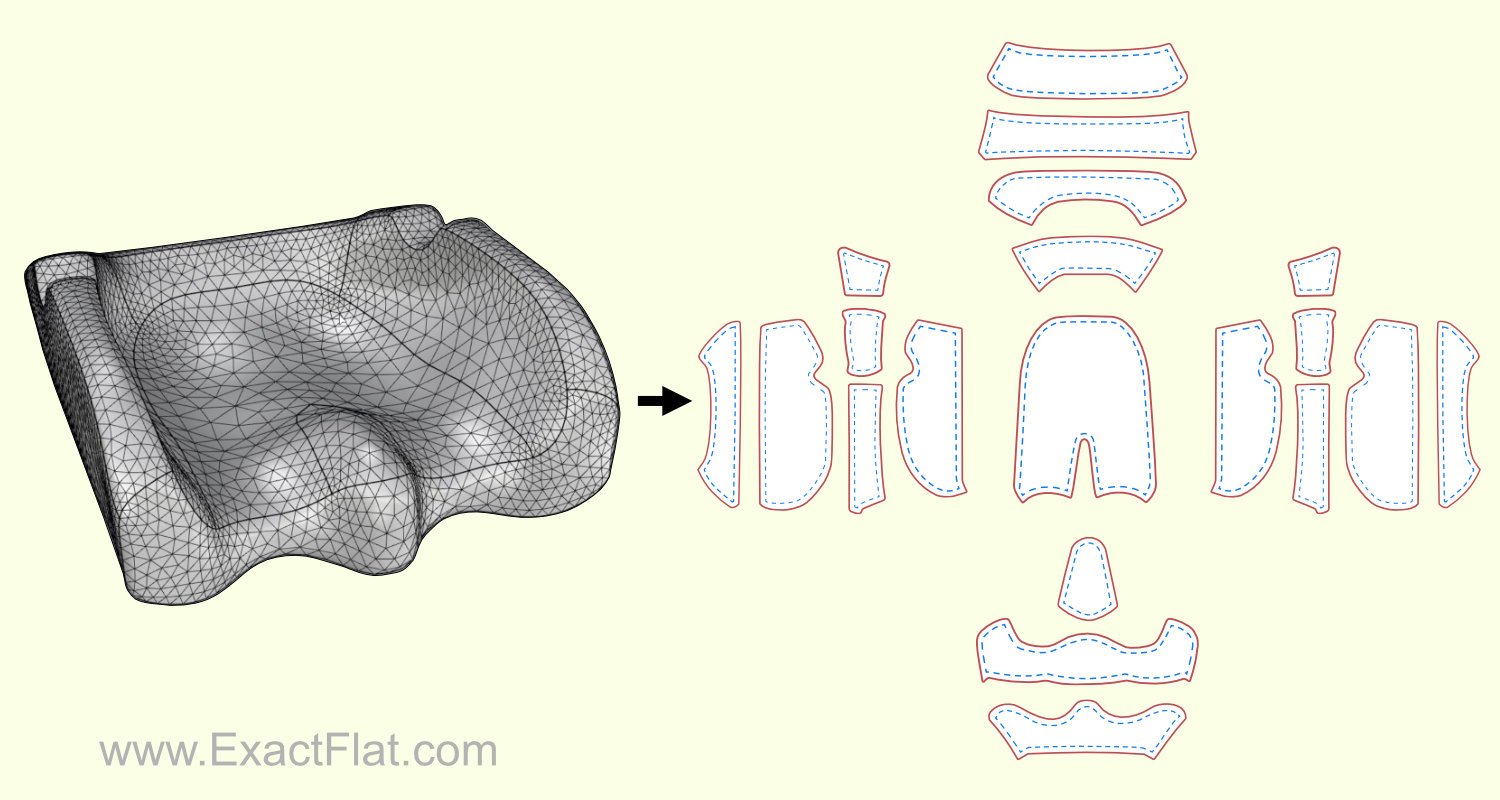

3D Motorcycle seat scan. 3D to 2D flattening and 2D pattern making with ExactFlat.

Remesh

Uniform & Adaptive re-mesher: Quickly optimize mesh structure by refining the size, shape, and count of mesh elements.

Repair

Mesh Validation & Repair: Easily detect and correct issues such as non-manifold edges, holes, and other mesh irregularities.

De-wrinkle

Wrinkle/flipped triangle removal: Identify and quickly eliminate unwanted wrinkles, folds, and flipped triangles.

3D scan of automotive seat. 3D to 2D flattening and pattern making with ExactFat.

Markings

Easily Convert 3D to 2D Markings: Trace markings in 3D and automatically convert those markings directly onto 2D pattern pieces with computer precision.

Layers

Simple Multi-Layered Surface Flattening: Easily handle parts with multiple layers, ensuring precise 3D to 2D conversion.

High Piece Count

Higher-Volume 3D to 2D Conversion: Efficiently complete projects with up to 150+ pattern pieces, thanks to ExactFlat’s multi-threaded processing, allowing simultaneous 3D to 2D conversion for faster results.

3D to 2D flattening on custom measurements for bespoke shoes. Patterns made with ExactFlat.

Preserve Boundary

Preserve Boundary Length vs. Relax Surface Area: Flexibility to prioritize preserving edge boundary length, or prioritizing surface area relaxation where appropriate.

Adjust Strain

Adjustable Target Strain: Customize target strain at both global and local levels, ensuring your patterns fit as intended, whether more relaxed or tighter.

Grain lines

Easily Add Grain Lines: Quickly add grain lines to your patterns, ensuring accurate alignment and fabric handling.

Custom seat with double curved surfaces. 3D to 2D flattening and pattern making with ExactFlat.

Material Types

Material Type Options: Tailor your 3D to 2D conversion based on material types with linear isotropic, orthotropic, or bias material 3D to 2D flattening options.

Material Stretch

Material Stretch Properties: Incorporate and assign material stretch properties that can be used in ExactFlat’s 3D to 2D flattening algorithms so you can improve the fit of 2D patterns.

Surface Relaxation

Advanced Geometry Relaxation: Easily tackle double curved surfaces of any complexity with multiple algorithms, including smart fracture, pelt, press, relax curvature, or CCM round, to ensure faster more accurate pattern fit optimization.

3D CAD model of a carbon fibre air intake. 3D to 2D flattening with ExactFlat.

Piece Layout

Faster 2D Pattern Piece Arrangement: Quickly arrange your 2D pattern pieces to visually mimic the final sewn assembly layout with ExactFlat’s pattern piece linking Find Tool.

Seams

Easier Seam Allowances & End Conditions: Using pattern-linking technology, apply seam allowances and end conditions to individual or adjacent pattern piece edges automatically. This makes pattern making faster and error free.

Notches

More Accurate Notch Points & Notch Chains/Arrays: Using pattern-linking technology, easily apply alignment notches to individual or adjacent pattern pieces edges, making notch placement faster and error free.

Automated 3D to 2D pattern making in the cloud. 3D model of custom sized blue jeans flattened into 2D patterns with ExactFlat.

Cutter Profiles

Faster Cut File Export: Save time by applying saved cutter profiles to your export files. This ensures compatibility with your selected cutting machines.

File Export

Files Types: Enjoy the flexibility to choose between DXF, PDF or 3D CAD file formats so you can continue your work in whatever format works for your needs.

File Import

3D Scanned & Digitized Data: Import files from 3D scanners, digitizing probes, or various 3D CAD file formats.

Make Better Patterns Faster. We’ll Show You How.

Easy to Learn For Same Day Results

ExactFlat is better because its modular workflow and simple user interface make complex tasks easy to learn (2-4 hours) so users can improve productivity on day one.

Ford Mustang front bumper 3D scan. 3D to 2D flattening with ExactFlat.

Workflow

Easy to Learn Workflow: The ExactFlat workflow is sectioned into small modular steps that make complex tasks easy. That is why it is easy to learn and easy to use.

Interface

Simple User Interface: The ExactFlat interface supports ExactFlats small modular steps philosophy. The clean, straightforward design makes it easy for users to navigate and complete projects faster.

Training

Productivity

Minimal Training Time Required: ExactFlat training is faster due to our modular workflow and simple interface. It takes about 2-4 hours of training to be ready for your first project.

Same-Day Productivity Improvement: New users can typically achieve productivity improvement faster, often within the first time use and on the first day.

Make Better Patterns Faster. We’ll Show You How.

Automotive car seat bun 3D to 2D flattening and pattern making using ExactFlat.

Who Uses ExactFlat

ExactFlat is used by companies in 25+ countries around the world. These companies create products incorporating fabricated soft goods and share the goal of making better patterns faster.

If you want to make better patterns faster,

why not reach and out and we’ll show you how.

Lear – Lear uses ExactFlat for automotive interiors and seating

https://www.lear.com/Site/Technology/seating.aspx

Hanse Yachts– Hanse Yachts uses ExactFlat for boat hulls and interiors

https://www.hanseyachtsag.com/hanse/gb/hanse/

Ball Aerospace – Ball Aerospace uses ExactFlat for satellite covers and wraps.

https://www.ball.com/aerospace

Advanced Thermal – Advanced Thermal uses ExactFlat for the fabrication of turbine insulation systems.

http://advancethermal.com/

Land Rover – Jaguar Landrover uses ExactFlat for automotive interiors.

https://www.jaguarlandrover.com/

Diab – Diab uses ExactFlat for composite fabrication.

https://www.diabgroup.com

Eastman Chemical – Eastman uses ExactFlat for paint protection film.

https://www.eastman.com/pages/home.aspx

John’s Hopkins University – John’s Hopkins applied physics laboratory uses ExactFlat for composite engineering. https://www.jhuapl.edu/

Raven Aerostar– Raven Aerostar uses ExactFlat for high altitude inflatables

https://ravenaerostar.com/

Yamaha Marine – Yamaha Marine uses ExactFlat for marine canvas and upholsetery

https://yamaha-motor.com/

Haworth Office Furniture – Howarth uses ExactFlat for upholstered furniture

https://www.haworth.com/na/en.html

Tesla – Tesla uses ExactFlat in the design and fabrication of composite parts

https://www.tesla.com

Cameron Balloons UK - Cameron Balloons use ExactFlat in the fabrication hot-air balloons and almost every conceivable type of lighter-than-air craft.

http://www.cameronballoons.co.uk

Lockheed Martin – Lockheed Martin uses ExactFlat for 3D to 2D conversion

https://www.lockheedmartin.com